Posted by Chrom Tech on 14th Oct 2025

ASK BEN | 4 Simple Steps to Find the Right GC Liner

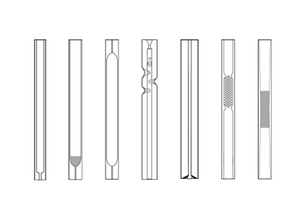

Choosing the right GC inlet liner is essential for achieving accurate and reproducible gas chromatography results. The liner ensures that the correct amount of sample is transferred to the GC column while maintaining sample integrity and minimizing analyte loss. With multiple liner types available, understanding the differences between designs and applications will help you make the best choice for your analysis.

GC Basics: Injection Techniques

Before selecting a liner, it’s important to understand your injection method. The two most common GC injection techniques are split and splitless, and each requires a specific liner type.

Split Injection

- Used for samples with moderate to high analyte concentrations.

- High flow rates produce sharp, narrow peaks and minimize sample interaction time.

- Ideal for highly sensitive detectors since most of the sample is vented, preventing overload.

Splitless Injection

- Used for low-concentration analytes or when employing less sensitive detectors.

- Delivers more of the sample to the column for improved detection limits.

- Lower flow rates may broaden peaks, and care must be taken to prevent analyte degradation or adsorption.

How to Choose the Right GC Inlet Liner

Once you know whether your method uses split or splitless injection, you can narrow down liner options by considering four main factors:

- Injection Type: Determine whether your method uses split or splitless injection. This will immediately narrow your selection to the corresponding liner designs.

- Internal Shape: Split liners are open at the bottom, allowing carrier gas to flow evenly across the sample. Splitless liners typically feature a tapered bottom to funnel the sample efficiently onto the column, minimizing active site contact and sample loss.

- Packing Material (Wool): Some liners include glass wool to enhance vaporization by increasing surface area. However, unpacked liners are less expensive and reduce carryover risk. When wool is included, its placement (top or middle) affects sample behavior and cleanliness.

- Internal Diameter (ID): The liner’s ID must accommodate the vaporized sample volume. Smaller IDs yield narrower peaks, but ensure your sample doesn’t expand beyond the liner volume, which could cause backflow or poor reproducibility.

Liners for Gas Phase Samples

For samples already in the gas phase—such as headspace, purge-and-trap, or air monitoring applications—a straight liner with a narrow ID and no wool is ideal. These liners minimize diffusion before the sample reaches the column, serving as a direct, efficient pathway for gas introduction rather than a vaporization chamber.

Conclusion

Selecting the proper GC liner begins with understanding your injection method and sample characteristics. By choosing the right shape, packing, and diameter, you’ll achieve consistent, high-quality chromatographic performance. If you’re optimizing your GC setup, consider pairing your system with reliable Parker gas generators to ensure stable carrier gas delivery and improved instrument uptime. For help identifying the best liner or gas setup for your application, contact our support team today.

Frequently Asked Questions About GC Liners

What does a GC inlet liner do?

The GC inlet liner provides a chamber for sample vaporization and transfer into the column. Choosing the correct liner ensures efficient vaporization, consistent sample transfer, and minimized analyte degradation or adsorption.

How do I know if I need a split or splitless liner?

If your analyte concentrations are high, a split liner is best because most of the sample is vented. For trace-level analysis or low-concentration samples, choose a splitless liner to deliver more analyte to the column.

Should I choose a liner with or without wool?

Liners with wool improve sample vaporization and help trap particulates, while liners without wool reduce the risk of carryover and active compound adsorption. Your choice depends on sample composition and method sensitivity.