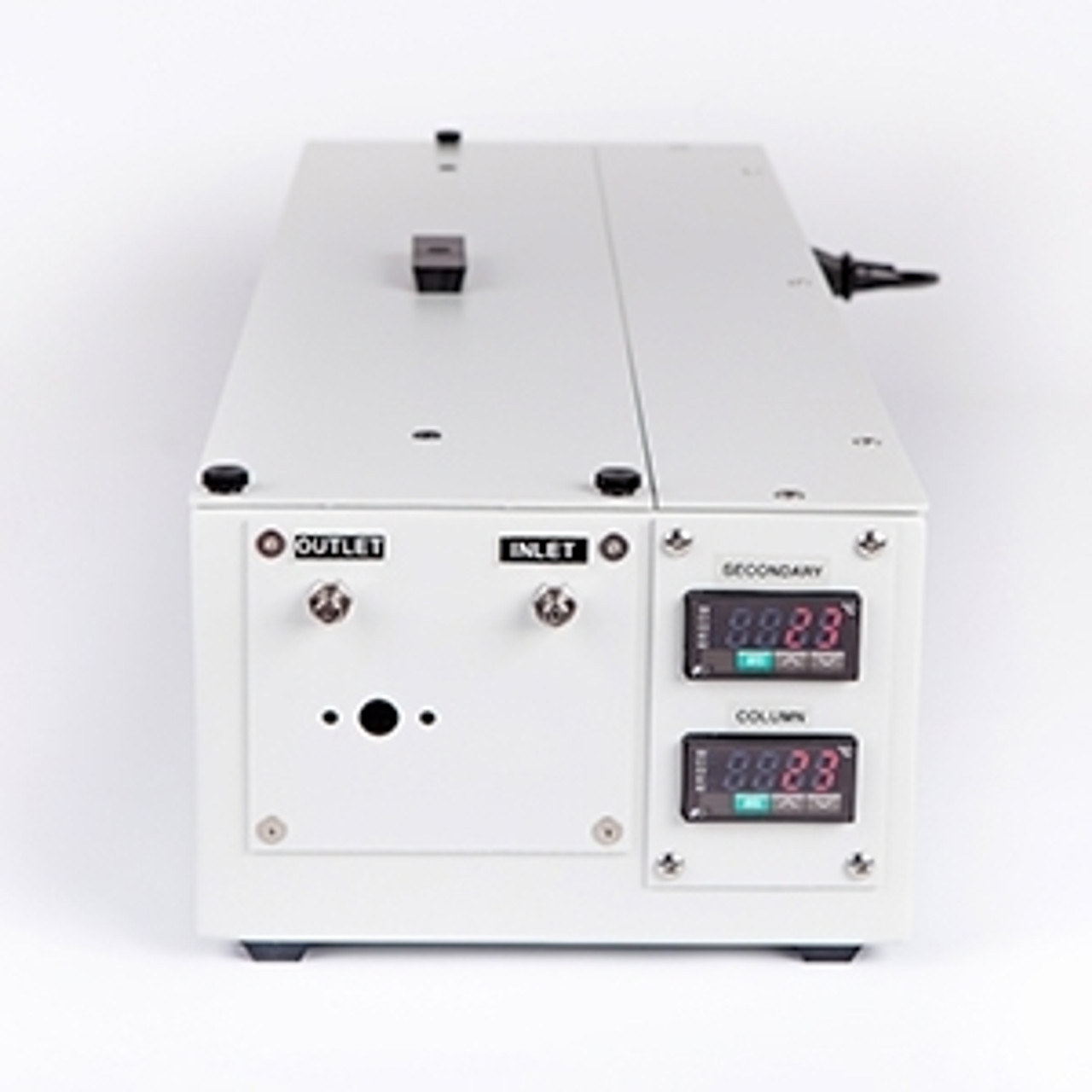

H-105 Column Heater

Chrom Tech H-105 Column Heater

- Heats multiple columns

- Preheats mobile phase

- Injection or switching valves in the heated compartment

- Temperature stability

The H-105's micropressor controlled heating provides stable and accurate temperature control, reproducible retention times, and stable baselines for temperature sensitive detectors. Increasing column temperatures reduces peak tailing due to surface silanol interactions, improves efficiency, reduces backpressure and prevents column contamination.

The column, preheater, and installed valves in the heated cavity are easily accessed through an insulated cover held in place on the top of the unit with thumbscrews. Inadvertant solvent leaks are easily detected and directed away from heater electronics by a drain tube in the heated compartment connected to a bulk head fitting on the back of unit.