29th Sep 2020

How To Maximize HPLC Column Lifetime

All chromatographic columns deteriorate over time. Some of the biggest factors that contribute to the degradation of HPLC columns include injecting your sample, as the sample matrix can have remaining proteins, lipids, and particulates. In addition to your sample, the mobile phase and the HPLC system can also contribute to the accumulation of fine particles. These particles can lead to an increase in pressure, which will further decrease the column’s lifetime.

Here’s how to maximize HPLC column lifetime to proactively avoid premature degradation.

Sample Preparation and Clean-Up

Sample preparation and clean-up are done for a myriad of reasons, including buffer exchange, sample concentration, and filtration to remove contaminants and particles. Common sample preparation techniques include solid-phase extraction (SPE), liquid-liquid extraction (LLE), and chromatography syringe filters.

SPE is used to clean up a sample before analysis by using a solid absorbent cartridge to absorb select contaminants from the sample.

LLE works by extracting compounds from the eluent, where the two are not miscible.

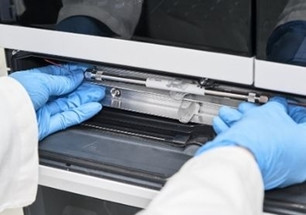

Syringe filters remove particles from a liquid sample by filtering the sample through a porous membrane. Syringe filters are devices designed to connect to a plastic disposable syringe filled with the sample, which is then pushed through the porous membrane housed inside the syringe filter. Another option for filtering samples is by using our filter vials which are an all-in-one, single-step solution for filtration into a vial. For high throughput filtration, we also offer filter plates for easy automation of your sample preparation.

Solvent and Buffer Procedures

You should follow certain solvent and buffer procedures to protect your HPLC column lifetime, such as using fresh solvents, filtering buffers, and using the proper pH of the mobile phase.

You should also use fresh solvents and buffers to avoid bacterial growth, which can lead to column degradation. Make sure to filter out buffers after you have prepared them to rid the buffer of any precipitation of salts or particulate matter that may have been present at the time the buffer was made. You may also consider following the recommended pH of the mobile phase. A pH that is too low can cause the ligand to hydrolyze and cleave from the stationary phase, reducing retention and efficiency of the column.

Filters

Inline solvent filters, pre-column filters, and guard columns all improve the HPLC column’s lifetime by filtering and trapping harmful particles.

Inline solvent filters sit between the pump and injector to prevent harmful particles from reaching downstream components.

Pre-column filters are located after the injector and immediately before the column, with a specified porosity filter to sift out unwanted particles.

Guard columns are placed between the injector and the analytical column. These columns utilize packing material that is matched to the analytical column to trap materials that can build up and degrade the column.

Follow Operation Conditions

The last step in how to maximize HPLC column lifetime is to follow the manufacturer’s guidelines. The manual will typically cover sample preparation recommendations, pH range guidelines, and information on solvents, as well as maximum operating pressure advice imperative to column lifetimes.

For example, silica-based reversed-phase packings are very stable at room temperature for most mobile phase conditions between pH 2 and 8, whereas hybrid-silica particles extend the operational pH range from 1 to 12. However, if you increase the temperature, especially when you are working close to the pH limits of the packing material, column life may rapidly deteriorate.