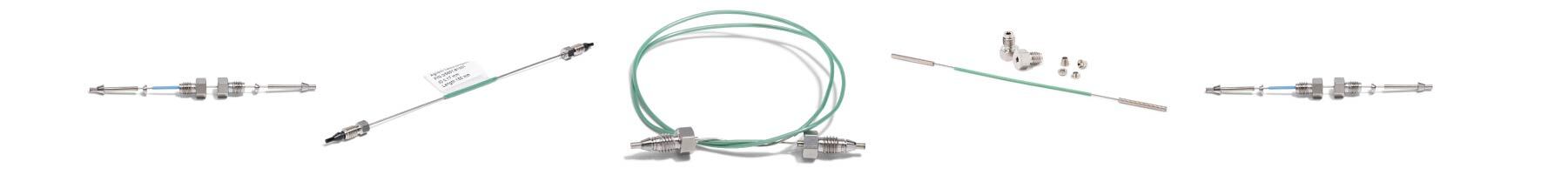

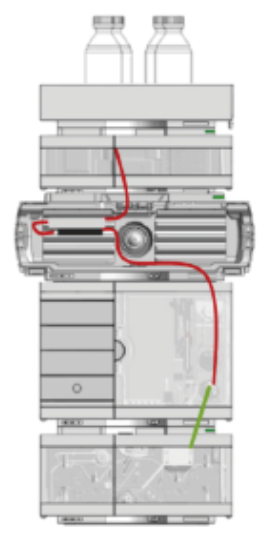

Capillaries and Connectors

Agilent capillaries, fittings, and connectors are engineered specifically for Agilent HPLC systems to maintain a secure, leak-free flow path and protect the accuracy of your chromatographic results. Each HPLC capillary is manufactured using Agilent’s precision laser-welding process, producing perfectly flat, burr-free ends that eliminate capillary-induced dead volume and prevent unnecessary peak distortion.

Our selection includes high-quality loop capillaries designed for a wide range of autosampler volumes and workflows. Available in both stainless steel and PEEK to accommodate different pressure requirements, these Agilent loop capillaries deliver reliable, high-precision performance across Agilent 1200-series autosamplers and other compatible LC instruments.

As an authorized Agilent distributor, Chrom Tech supplies only genuine Agilent capillaries, fittings, and flow-path components—ensuring OEM-level quality, validated performance, and trusted compatibility with your HPLC system. You can purchase with confidence knowing every part meets Agilent’s stringent manufacturing standards and is supported by Chrom Tech’s knowledgeable technical team.

| Internal Diameter (mm) | Color Code |

|---|---|

| 0.015 | Orange |

| 0.025 | Yellow |

| 0.05 | Beige |

| 0.075 | Black* |

| 0.1 | Purple |

| 0.12 | Red* |

| 0.17 | Green* |

| 0.20 / 0.25 | Blue |

| 0.3 | Grey |

| 0.5 | Bone White |

*MP35N versions include an orange identifying stripe.

| Key | Description |

|---|---|

| W | Swagelok + 0.8 mm Port id |

| S | Swagelok + 1.6 mm Port id |

| M | Metric M4 + 0.8 mm Port id |

| E | Metric M3 + 1.6 mm Port id |

| U | Swagelok union |

| L | Long |

| X | Extra long |

| H | Long head |

| G | Small head SW 4 mm |

| N | Small head SW 5 mm |

| F | Finger-tight |

| V | 1200 bar |

| B | Bio |

| P | PEEK |